-

CNC Tornalama ve Frezeleme

-

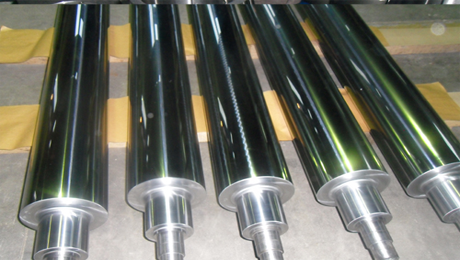

Krom Kaplı Merdaneler

-

Balans ve Sistem Kontrolü

-

Teknik & Özel Merdaneler

EĞRİ AÇICI MERDANELER

Eğri açıcı (Muz) merdaneler alüminyum folyo, plastik film, tekstil, kâğıt ve Tyre-Cord gibi ürünlerin kesim operasyonlarında kırışıklık gidermek ve üründe oluşan gevşek veya fazlalık kenarları ortadan kaldırmak için kullanılır.

Aşınmaya karşı dayanıklılık kazandırmak için yüksek hızlı uygulamalarda kauçuk kaplanmaktadır. Ayrıca yine hızlı uygulamalarda krom kaplı veya tamamen paslanmaz çelikten üretilmektedir.

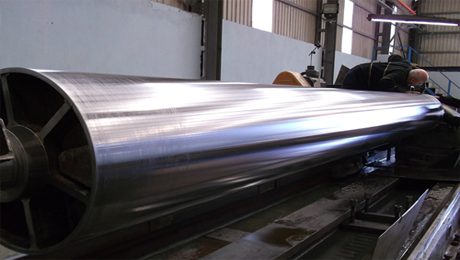

KALENDER MERDANELERİ

Kalender merdaneleri, tekstil, kâğıt, plastik ve lastik ürünlerin işlenmesinde kullanılmaktadırvebitmiş ürünün kalitesi ile doğrudan ilişkilidir. HTV Makine olarak müşterilerimizle birlikte tasarım sürecinde dahi iş birliği sağlamaktayız.

Max 1.600mm çap ve 11.000mm boyda 5.000kg’a kadar kalender merdanesi üretmekteyiz. Aynı zamanda talep doğrultusunda krom kaplama, elastomer kaplama, super-finish ve desenleme işlemlerini yapmaktayız.

ISITMA / SOĞUTMA MERDANELERİ

Üretim teknolojilerinin artan talepleri doğrultusunda daha hızlı ve daha az ısısal sapmaya sahip, yüksek sıcaklıklarda ve basınçlarda çalışabilen merdaneler gereklidir. Tasarım ve mühendislik çalışmalarımız ile müşterilerimizin talep ettiği tolerans ve teknolojileri üretiyoruz.

Kullanım amaçlarına göre tek veya çift cidarlı, tek girişli veya çok girişli yağ, su veya elektrik ısıtmalı olarak üretimini gerçekleştirdiğimiz silindirlerin yüzeylerini müşterilerimizin istekleri doğrultusunda krom kaplı, mat, taşlanmış veya desenlenmiş olarak üretmekteyiz.

ALÜMİNYUM MERDANELER

Alüminyum merdaneler, mükemmel ekstrüzyon ile birlikte gelen dayanım/ağırlık oranının yüksek olması, düşük eylemsizlik momenti ve düşük salgı değerlerine sahip olduğu için tercih edilmektedir.

Standart olarak 60mm ile 200mm çap aralığında ve 11000mm boya kadar ve aynı zamanda müşterilerimizin talepleri doğrultusunda özel ölçülerde live-shaft veya dead-shaft olarakalüminyum merdane üretebiliyoruz.

Alüminyum merdaneleri, 3 düzlemli dinamik balansı alınmış ve müşteri talebi doğrultusunda yüzey işlemleri (ısıl işlem veya kaplama) yapılmış olarak üretiyoruz.